Delving into the realm of fleet management, The True Cost of Fleet Vehicle Downtime sheds light on the significant repercussions of vehicles being out of commission. From financial losses to operational disruptions, this topic explores the hidden expenses that businesses often overlook.

As we unravel the layers of costs associated with downtime, it becomes evident why efficient fleet management is crucial for any company reliant on a fleet of vehicles.

Understanding Fleet Vehicle Downtime

Fleet vehicle downtime refers to the period when a commercial vehicle is out of service and unable to perform its intended tasks. This downtime can have a significant impact on businesses, leading to decreased productivity, increased operational costs, and potential loss of revenue.Industries heavily reliant on fleet vehicles include transportation and logistics, construction, delivery services, and emergency services.

For example, transportation companies depend on their fleet to deliver goods and services efficiently, while construction companies require vehicles to transport materials and equipment to job sites.Several factors contribute to fleet vehicle downtime, including mechanical issues, accidents, maintenance delays, and driver shortages.

Mechanical issues such as engine failures, tire blowouts, or brake problems can cause unexpected downtime, requiring immediate repairs. Accidents can also lead to vehicle damage and lengthy repair times, further increasing downtime. Maintenance delays, if not properly scheduled and executed, can result in breakdowns and extended periods of inactivity.

Lastly, driver shortages can impact fleet operations, leading to vehicles sitting idle without drivers to operate them effectively.

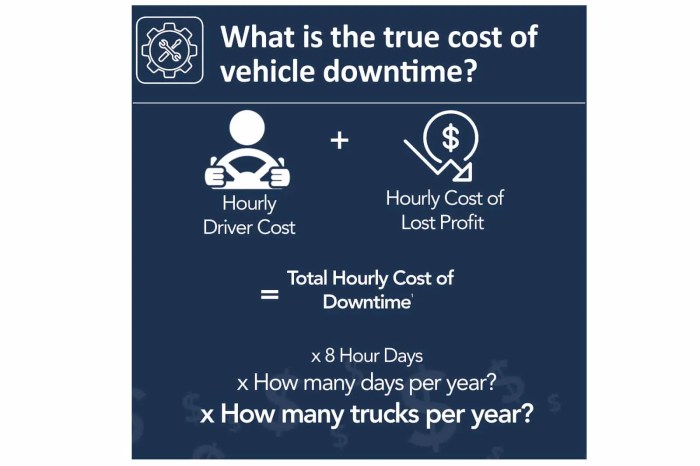

Calculating the Costs

When fleet vehicles experience downtime, it can result in various direct and indirect costs for a company. Direct costs include expenses related to repairs, parts replacement, and labor costs for mechanics. Indirect costs, on the other hand, encompass lost revenue due to missed deliveries, customer dissatisfaction, and potential damage to the company's reputation.

Methods for Calculating Financial Impact

- One common method is to calculate the cost per hour of downtime for each vehicle in the fleet. This involves factoring in the average revenue generated by the vehicle per hour and comparing it to the expenses incurred during the downtime.

- Another approach is to consider the overall impact on the company's bottom line. By analyzing how downtime affects productivity, customer satisfaction, and overall operations, a more comprehensive picture of the financial impact can be obtained.

Maintenance Schedule’s Impact on Downtime Costs

Regular maintenance schedules play a crucial role in minimizing fleet vehicle downtime costs. By adhering to a strict maintenance routine, companies can prevent unexpected breakdowns, extend the lifespan of their vehicles, and identify potential issues before they escalate. This proactive approach helps reduce both direct and indirect costs associated with downtime, ultimately saving the company money in the long run.

Strategies to Reduce Downtime

Preventative maintenance is key to minimizing fleet vehicle downtime. By implementing regular maintenance schedules and inspections, potential issues can be identified and resolved before they lead to costly breakdowns.Utilizing technology plays a crucial role in monitoring and predicting maintenance needs.

Fleet management software can track vehicle performance, alerting managers to upcoming maintenance tasks based on mileage or usage. This proactive approach helps prevent unexpected downtime by addressing maintenance needs in a timely manner.

Best Practices for Optimizing Fleet Operations

- Establish a comprehensive maintenance schedule for each vehicle in the fleet, including routine inspections and servicing.

- Utilize telematics systems to monitor vehicle health and performance in real-time, allowing for immediate intervention when issues arise.

- Implement driver training programs to promote safe and efficient driving practices, reducing wear and tear on vehicles.

- Regularly review and analyze maintenance data to identify trends and patterns that can help predict future maintenance needs.

Impact on Productivity and Customer Service

When fleet vehicles experience downtime, it can have a significant impact on overall productivity and customer service. The inability to use vehicles for transportation or delivery purposes can disrupt schedules, delay shipments, and ultimately affect the efficiency of operations.

Productivity Loss

Fleet vehicle downtime directly correlates to a loss in productivity for businesses. When vehicles are out of commission, employees may not be able to reach their destinations on time, leading to missed appointments or delayed tasks. This can result in a domino effect, causing work backlog and decreased output levels.

- Delayed service calls or deliveries

- Inefficient use of resources

- Increased overtime costs to catch up on delayed work

Customer Service and Satisfaction

The repercussions of fleet vehicle downtime on customer service can be detrimental. When deliveries or services are delayed due to vehicle issues, customers may become frustrated or dissatisfied with the level of service provided. This can lead to a tarnished reputation, loss of customers, and ultimately, a decrease in revenue.

- Customer complaints and negative reviews

- Loss of repeat business and potential referrals

- Decreased customer loyalty and trust

Examples of Mitigation Strategies

Businesses have implemented various strategies to reduce the impact of fleet vehicle downtime on service delivery. Some of these include proactive maintenance schedules, investing in backup vehicles, and utilizing fleet management software to track vehicle health and performance.

- Partnering with reliable maintenance providers for regular servicing

- Implementing predictive maintenance techniques to address issues before they escalate

- Utilizing real-time tracking and monitoring systems to optimize vehicle usage

Final Thoughts

In conclusion, The True Cost of Fleet Vehicle Downtime highlights the intricate web of expenses and inefficiencies that arise when vehicles are not operating optimally. By implementing strategic measures to minimize downtime, businesses can enhance productivity, improve customer service, and ultimately bolster their bottom line.

Query Resolution

What are the direct costs associated with fleet vehicle downtime?

Direct costs include repairs, replacement parts, and labor expenses incurred to get vehicles back on the road.

How can technology help in reducing fleet vehicle downtime?

Technology aids in monitoring vehicle performance, predicting maintenance needs, and scheduling proactive repairs to prevent unexpected breakdowns.

Why is optimizing fleet operations crucial in minimizing downtime?

Optimizing fleet operations ensures efficient route planning, timely maintenance, and proper driver training, all of which contribute to reducing downtime and maximizing productivity.